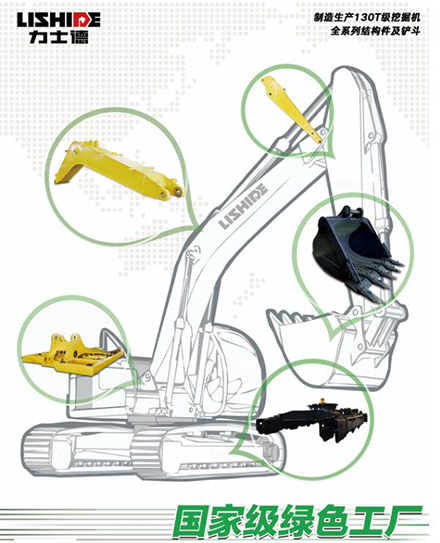

OUR INTRODUCTIONParts Introduction

Lishide Construction Machinery Co., Ltd. is not only a professional excavator manufacturer, but also an enterprise specializing in the production of construction machinery structural parts such as excavators, loaders and rollers. Taking lean manufacturing as the foundation of the enterprise, insisting on independent research and development, manufacturing of key components, and key process control, it has laid a solid foundation in hardware platform, process system and other aspects, forming a lean production system with core competitiveness.

The company undertakes the processing and manufacturing of external structural parts, comprising a discharging workshop, a welding workshop, a machining workshop, a shot blasting workshop, a painting workshop, and a standardized workshop with a floor space of more than 40,000 square meters. The company has a large number of advanced Messer plasma cutting machines, IGM welding robots, Korean precision and Doosan CNC machining centers, pass-through shot blasting and painting lines and other production equipment, realizing automation of welding and machining, and guaranteeing the processing quality of key parts.

The company has built a new standardized workshop for structural parts of more than 20,000 square meters, and introduced a large number of advanced production equipments, such as laser cutting machine, 800t bending machine and welding robot, etc. The company has the ability to manufacture the whole series of structural parts from 0.8T to 130T grade with an annual output of 10,000 tons. Various detailed and easy-to-understand operating instructions and innovative jigs and fixtures have ensured the standardized production of products, giving the company a full range of structural components manufacturing capacity from 0.8T to 130T, with an annual output of more than 10,000 sets of structural components for excavators.

-

CNC Welding Equipment

- The company has 10 sets of IGM large-sized welding robots for welding structural assemblies; 10 sets of Fanuc small-sized welding robots for welding small structural components; and one automatic flow production line for digging buckets, fully realizing the welding automation of structural components.

-

CNC Unloading Equipment

- The company now has 6 sets of Messer plasma CNC unloading and OTC breaching machines, and 2 sets of new 20Kw laser cutting machines, which can cut plates of thicknesses between 4-100mm, meeting the cutting requirements of structural parts in unloading production.

-

CNC Machining Equipment

- The company has 8 sets of Korean precision and Doosan machining equipment, including 3 sets of CNC horizontal milling and boring machining centers and 4 sets of CNC double-sided boring and milling machining centers, which are capable of processing various types of construction machinery structural parts. The company has a set of three-dimensional coordinate measuring instrument and a set of portable three-dimensional coordinate measuring instrument, which are used to test all kinds of dimensions and ensure that the products are qualified.

-

Painting Equipment

- The company has 1 pass-through shot blasting coating line, including shot blasting room (16 heads), blowing room, primer spraying room, primer drying room, grinding room, top coating room, leveling room, drying room and other 8 studios, consisting of more than a dozen processes.